Just like other stone crusher machines, jaw crusher also needs a regular repair and maintenance after a certain time of working, or it will get decreased service life because of severe wear of important parts.

So many customers have common misconception that jaw plates only need repair when appearing flat, holes, cracks. Actually if jaw plates wears badly, it is not only hard to repair but seriously affects the normal working of other parts, which then will take a great sum of money to change a jaw plate and maintain other parts.

hole, flat, cracks on jaw crusher plate

Although the main crushing process is complemented by jaw plates, the crucial parts that give a motion to the moveable jaw plate are toggle plate, pitman bearing and flywheel.

The pitman drives the moveable jaw dies to push stone material towards stationary jaws, which would create strong pressing forces to both jaw dies. Therefore, if the pitman cannot get lubrication in time, it will be broken under the high pressure of material and interrupt the whole work.

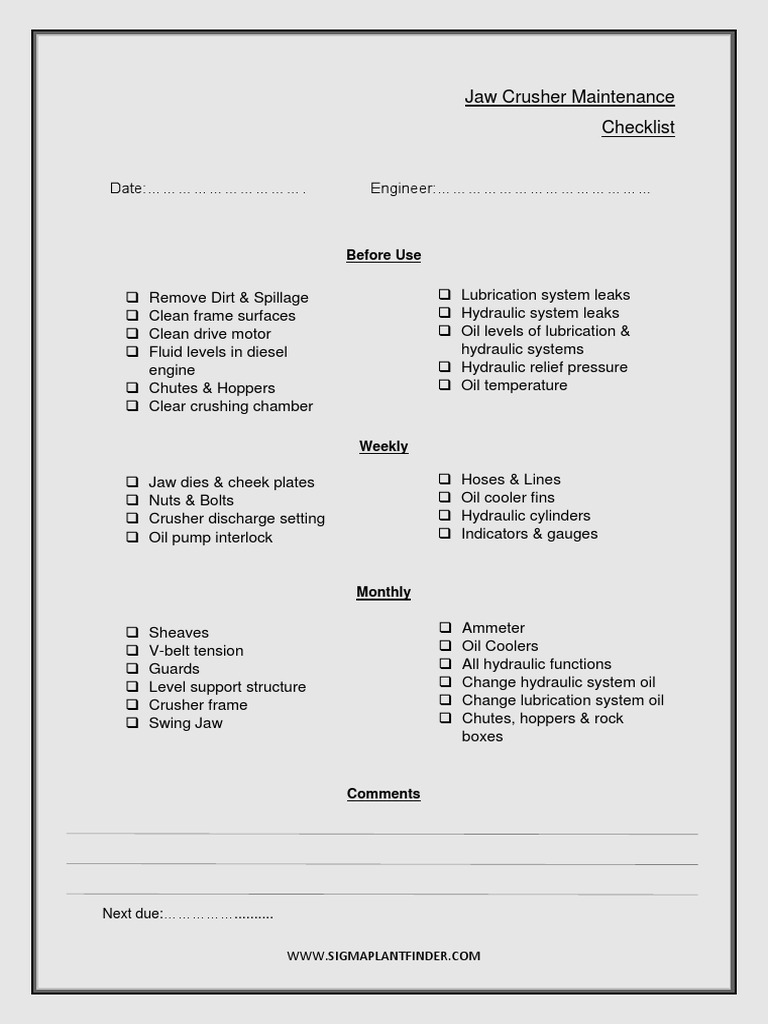

Proper plan and preparation make the whole repair and maintenance ordered and effective, which helps operators save time, cost, and enhance their safety. You can make a checklist just like the following chart in which you can list need-checked jaw crusher parts with a different period then making a mark if you are done with them. This not only prevents missed inspections, but also makes the arrangement clear, and saves a lot of time.

a template of jaw crusher checklist

The lubrication of the interface between the parts of the jaw crusher is very important. It can minimize the friction generated during the operation, make the whole jaw crusher run smoothly, and extend its service life.

Unlike gyratory crushers, the main lubrication used in jaw crushers is grease instead of oil. When using grease, there may be several different ways to inject it into the necessary lubrication points. It can be operated manually with a grease gun, an oiler or metering pump.

Video of automatic lubrication system of a jaw crusher

Which parts need to be lubricated?

Eccentric shaft (pitman bearing): It is behind the moveable jaw plate, and together with flywheel with toggle plate to create a motion. So, the most important thing you must do is keeping a regular lubrication to eccentric shaft, or you will spend more than four hours in changing a new one when it is broken.

Main shaft To keep the main shaft in good lubricating situation, you need to guarantee enough geese between thrust plate.The grease added to the bearing box needs to occupy about 50% of its space and be replaced every 3-6 months. When changing the engine oil, please use clean gasoline or kerosene to clean the roller bearing raceways.

There are different jaw plates material in the market, and some of them suits for hard stone while other is not. Therefore, you have to choose the right jaw plate for your crusher. For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production.

It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance.

How to replace jaw crusher plates?

The function of toggle plate is to adjust the outlet of the jaw crusher to the desired size. There are two specific methods: one is to replace the support pad between the toggle plate and the body frame, and the other is to adjust the two wedges between the toggle and the body frame.

Fote Company has more than 40-year manufacturing experience, mainly engineering different types of jaw crushers including PE jaw crusher, Dodge jaw crusher, Blake type jaw crusher(double toggle jaw crushers), single toggle jaw cruhser, etc., and all of them can be customized.

Author : Jordan Jordan is the writer of the blog with a broad knowledge of this industry. Most importantly, he hopes to help you in your projects sincerely.

FTM Machinery- Green and Intelligent Mining Machinery Manufacturing and Export Base

Based on high quality and perfect after-sales service, our products have been exported to more than 120 countries and regions. FTM Machinery has become the first choice for over 2,000,000 customers.

No.168, Wutong Street, High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China

Copyright © Fote machinery - Sitemap - Privacy